hi, Changed the engine Oil in my new to me Car, took the undercover off to get to the drain plug and noticed a 50mm crack in the Sump, very very slight weep.

Maybe in the summer I could remove it and have it welded.

In the mean time has anyone fixed a alloy sump with a glue like JBWeld or something?

Problem is normally getting the surface clean enough to allow whatever you bung on there to stick and seal, with a constant supply of oil above it. Accept the slight leak, and look for a replacement sump?

If you're taking it off then you can easily make a permanent job.

Brake/clutch/parts cleaner (as it's called) is a must have for getting it clean of oil, nothing is better.

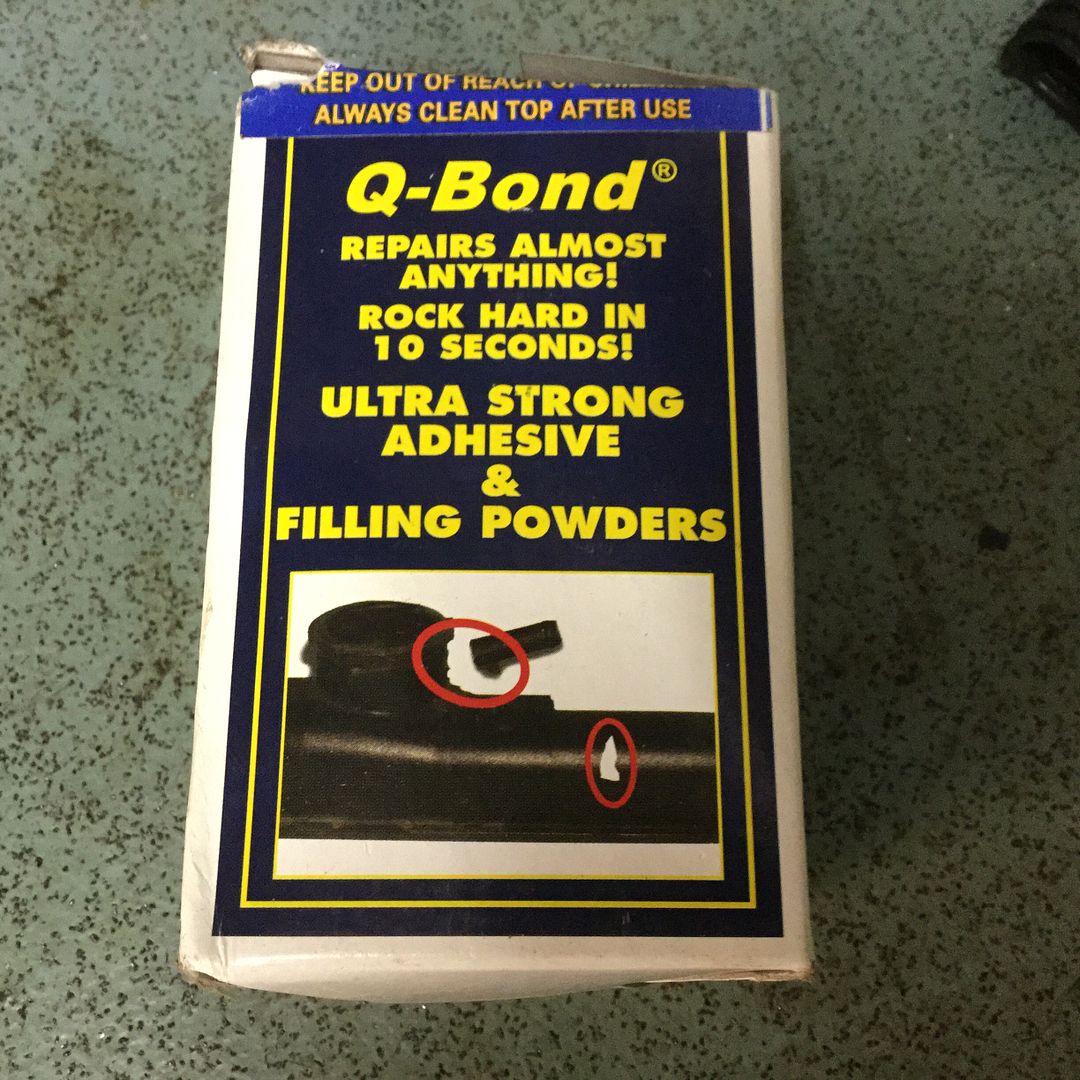

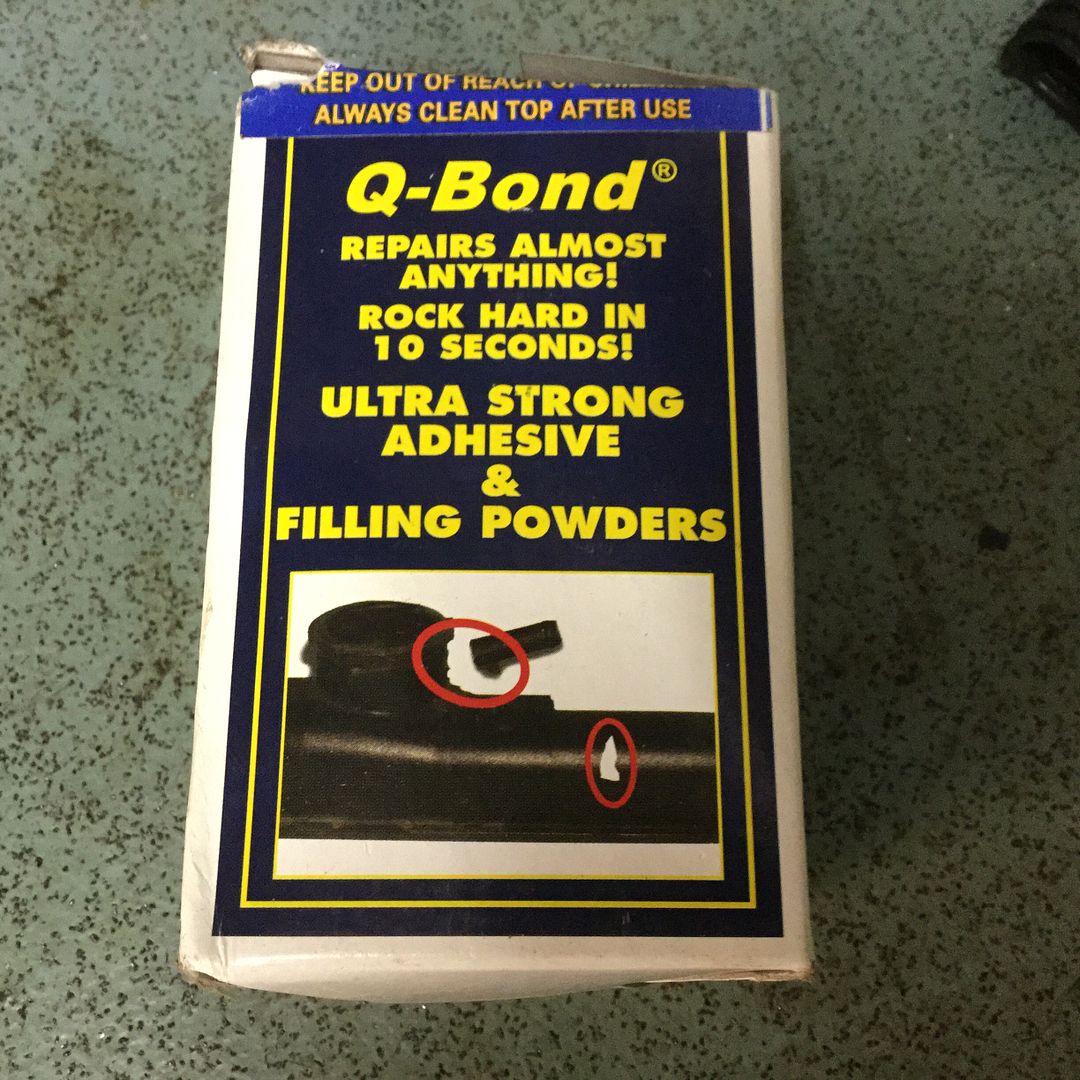

My choice to fill/cover the damage would be Q bond, follow the instructions and apply in layers (which take seconds to cure) and you'll quickly have a very, very solid repair far superior to anything like JB weld.

Another vote for Qbond, worth keeping one in the workshop at all times.

Plastic Padding Chemical Metal, works on most things and has been around for years and stood the test of time.

Fixed most industrial equipment ranging from large cast gearboxes to car fuel tanks with it, you do need to prepare the surface correctly which would mean draining the sump, cleaning the leaking area, abrading it correctly, then applying the product. You mix it like car body filler and apply it quickly as it goes off quickly, and you can sand it flat.

Yeah Belzona is still used worldwide in the oil industry for some pretty heavy-duty (and permanent) repairs. Not cheap though.

If you are going to use a filler do it on the out side in case a bit breaks off. Out don't want. That in your oil

@B20

Just a few questions?

Any indication why or how it has bean cracked?

Were is the crack?

Dos it look like t has bean stricken or hit by anything?

It could be a crack forming from the inside, a friend had a Vauxhall Fontana (please don't hate him for that) his sump had a weeping crack Were his had oxidised from inside out, on the cold oil level line.

The repair/bodge we did on the Fontana, it was a temp thing what lasted 2 years until a sump was acquired.

Drain the oil.

Clean up the area, we used a 36grit disc to do that.

Using a Demel thing (cheepo battery tool) we made a grove in the crack and put a dimple at each end. We hoped/ thought it will stop it from spreading. It did, but the rust made another crack on the other side.

Warming the area up with a paint stripper allowed us, using a thinner or brake cleaner soaked rag to get a lot of the oil out.

Then using a Halfords Chemical metal we applied a decent application over the crack. letting it fully cure.

Then we painted over it with a marine clear latex product. But I guess Varnish will do. We used what we had to hand.

Had a few beers and in the morning refilled with oil.

We found out why it had cracked.

I once split a Pug 104 sump by re fitting it wrong. Ok that was steel.

I have seen a repair on a Emergency Genny set, the sump had cracked, nothing with anyone dropping it Boss. No. No.

The repair was a trip of metal and a sheet of rubber and latex glue (Evo stick, other glues are available) and it was pop riveted on. Still going now.